Press Release

Development of Next-generation Superconducting Coil~Realization of a Coil that can Withstand the World's Strongest Electromagnetic Force~

May 14, 2012

Chubu Electric Power Co.,Inc.

Superconducting technology enables handling of large-capacity currents and strong magnetic fields without the generation of electrical resistance or loss, which makes it an extremely attractive technology for the electric power field. Chubu Electric Power has been contracted by the New Energy and Industrial Technology Development Organization (NEDO) to develop superconducting magnetic energy storage (SMES), which stores electricity in a coil, as part of the "Technological Development of Yttrium-based Superconducting Power Equipment" project (Note 1), and is promoting development of a next-generation superconducting coil.

This development aims to develop a device that is smaller, has lower cost and a larger energy capacity than conventional metallic superconducting SMES, by using an yttrium-based compound (Note 2) in the superconducting wire materials.

Yttrium-based superconducting wire materials have a higher mechanical strength compared to metallic superconducting wire materials, so there are expectations for use in SMES, medical equipment, transport equipment, and other magnet applications that require strong magnetic fields. As such, active development efforts aimed at practical application are underway both in Japan and overseas.

Superconductivity enables generation of strong magnetic fields using large currents, but strong electromagnetic force works to elongate the superconducting wire materials. Superconducting coils have conventionally used a structure whereby the electromagnetic force is borne by the wire materials. This meant that the electromagnetic force was limited by the strength of the superconducting wire materials, so development of coils that can withstand even stronger electromagnetic force was desired.

Chubu Electric Power and the Tohoku University High Field Laboratory for Superconducting Materials have jointly developed a revolutionary method (patent pending) for bearing the electromagnetic force acting on the superconducting wire materials with the coil surface. Furthermore, combination with insulating coating technology using liquid resin enabled successful development of a coil that can withstand electromagnetic force twice that of a conventional yttrium-based superconducting coil and six times that of a metallic superconducting coil, making it the world's strongest coil to date.

For example, this technology enables SMES to store 10 times the energy of an yttrium-based superconducting coil of the same size. In addition, this technology can be applied not only to SMES, but also to superconducting magnets in all fields that use strong magnetic fields.

Features of this development

1 High-strength coil structure that bears the electromagnetic force acting on the superconducting wire materials with the coil surface

Metallic superconducting coils can withstand electromagnetic force up to around 300 to 400 MPa (Note 3). In addition, yttrium-based superconducting coils can withstand a maximum electromagnetic force of 1,000 MPa, which is the limit of the superconducting material strength.

The newly developed coil has a structure that can withstand electromagnetic force of approximately 2,000 MPa, making it the world's strongest superconducting coil to date. This effectively supports stronger electromagnetic force due to increased coil sizes, and enables the achievement of a high coil energy capacity in a compact size.

2 Development of insulating coating technology for superconducting wire materials using liquid resin

Electric insulation techniques for superconducting coils have conventionally consisted of wrapping resin tape around superconducting wire materials. However, resin tape gaps and unevenness lowered the insulating performance and adversely affected the dimensional accuracy of the coils.

This development coated superconducting wire materials with liquid resin that can harden at a temperature that does not adversely affect the superconducting characteristics, for the first time in the world. This succeeded in forming a flexible insulating coating that is not adversely affected by bending, which simultaneously ensured insulating performance and enhanced workability.

This development will be presented at the "24th International Cryogenic Engineering Conference and International Cryogenics Materials Conference 2012" held in Fukuoka from May 14 to May 18.

(Note 1) Chubu Electric Power is developing superconducting magnetic energy storage (SMES) jointly with Furukawa Electric Co., Ltd., Tohoku University, Waseda University and Kyoto University as a National Project directed by the Agency for Natural Resources and Energy within the Ministry of Economy, Trade and Industry.

When current is flowed to a ring in the superconducting state (superconducting coil) in which the electric resistance is zero, since there is no resistance, the current does not attenuate, and the electric energy can be stored as magnetic energy. SMES is an energy storage system that makes use of this principle, and features a fast electric power input/output speed and high energy storage efficiency, enabling instantaneous output of high power.

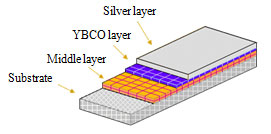

(Note 2) Superconducting wire materials that use an yttrium-based compound consisting of yttrium (Y), barium (Ba), copper (Cu) and oxygen (O) have a flat tape-shape created by forming multiple thin films on a metal substrate.

(Note 3) 100 MPa is the force applied to a string when an 8 kg weight is suspended by a 1 mm diameter string.